Decker D-20/40

Offer for Sale

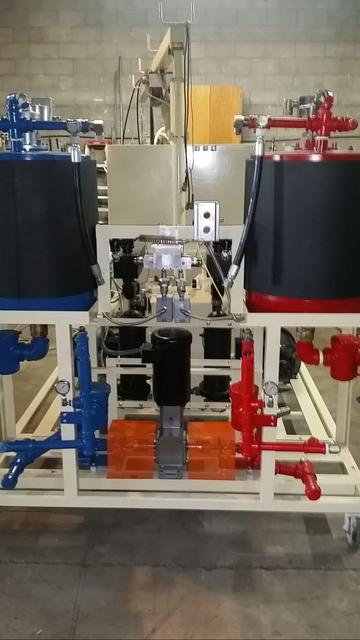

We are pleased to offer you the following system for your review. Decker DH20-1 machine build #812. The machine is loaded with the program originally provided. The unit is located on our floor in Toledo, OH. Footprint is 70” L-R x 84” F-B and mounted on lockable casters. The machine was recently rebuilt from a frame off restoration. The machines output would be 40 # per minute with appropriate size mix head. All components used are readily available from US manufacturers or Industrial Distributors. Hoses will be installed when chemical data is received. Some of the machines features include, but buyer should confirm:

Specifications

Ratio

Output gr./sec.

1 : 1

82 - 405

2 : 1

62 - 305

3 : 1

55 - 270

1 : 0.56

64 - 315

Metering Accuracy :

± 1.0%

Ratio :

5:1 to 1:5 Adjustable

Power Required :

480V, 3PH, 60Hz, 40 Amp

Shop Air Required:

Approx. 8 scfm @ 80-120 PSIG

Day Tanks (Polyol / Iso)

- 30 Gallon, fabricated from stainless steel

- Capacitance type level sensing

- Solenoid valves for automatic tank refill

- Shut off valve at the bottom of the tank

Filtration (Polyol / Iso)

- Basket type strainer mesh inserts for temperature conditioning loop

- Drain valve

- Basket type strainer mesh inserts for Metering Pump supply

- Drain valve

Metering Pumps (Polyol / Iso)

- Oilgear Size 4 Metering Pump

- Seal lube bottle for Iso pump

- 5 HP, 1165 RPM Motors

- Love Joy type couplings

- Pressure relief valves

- Low pressure by-pass valves for mix head

- High pressure safety switch

Mix Head

- Suitably sized L-Type Mix Head

- Adjustable type needles and orifices

- Proximity switch for clean out plunger

- Mix Head pendant with 3 shot selection

- Machine mounted boom approx.. 8’ radius

- Approx. 15’ Mix Head hose bundle

- Return style calibration

- High pressure safety switch in the return line day tank

-Mix Head Hydraulic Unit

-Approx. 30 gallon reservoir

- 6 gpm pump @2000 psi

- Return filter

- Hydraulic oil cooling

Temperature Control (Polyol / Iso)

- Low pressure Viking circulation pumps for material circulation

- Kidney loop design for conditioning of material

- High pressure safety switch

- Tube and shell heat exchangers for material cooling

- 3 kW heating

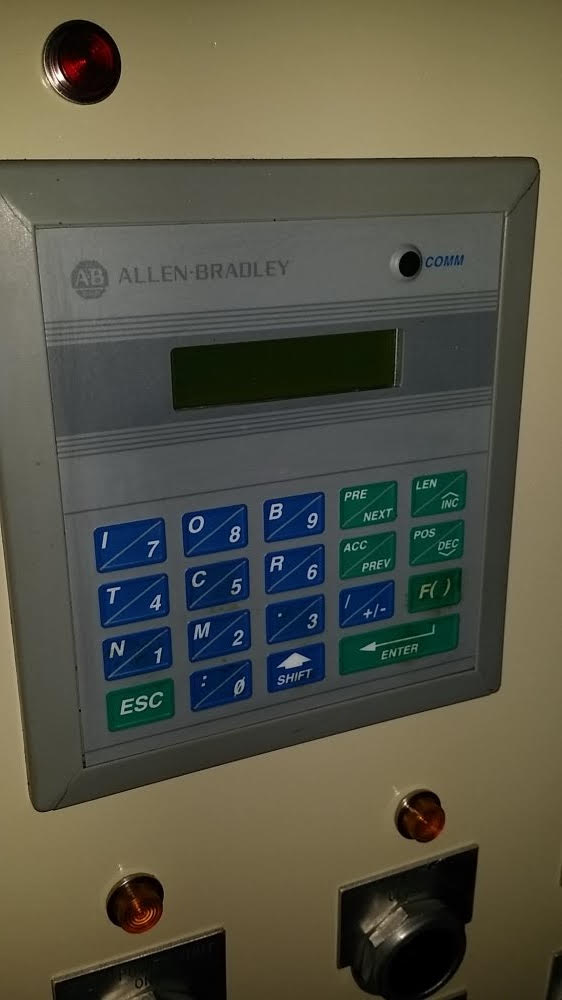

Controls

- Main control panel mounted to front of machine

- Main disconnect switch

- Allen – Bradley SLC 5/00 processor

- Allen – Bradley Operator Interface (HMI)

- Red Lion pressure displays

- Digital temperature controllers

- Fuses and circuit breakers

- Motor Starters

- Motor control push buttons

- Heater contactors

- Fault indicator lights

FOB………………..Toledo, OH warehouse……………………………………….$ CALL

Motor City Composites

Low Pressure Machines

High Pressure Machines

Lance Cylinder Machines

Hot Melt Machines

RIM Presses

Rexroth and Rotary Pumps

Mix Heads

Other RIM Items

Other Picked Items

Other Picked Items